In the vast and dynamic world of logistics, low bedding services play a unique and indispensable role. Essential for transporting heavy or oversized loads, they are the backbone of many industries, from construction and manufacturing to renewable energy. This comprehensive guide sheds light on the basic principles of low bedding services, their practical implications, and their pivotal role in modern transportation. As we navigate through the intricacies of this specialized field, we will discover how these services have evolved to meet the demands of a continuously progressing sector and how they contribute to our everyday lives. Buckle up for an enlightening journey into the world of low bedding!

What are Low Bedding Services?

Low bedding services are specialized transportation methods used to haul heavy or oversized loads that regular transportation solutions cannot accommodate. These services typically involve low-bed trailers or trucks, characterized by their low-lying deck and high load capacity. The design and construction of these vehicles allow them to carry large machinery, equipment, and even prefabricated structures, making them an invaluable asset in industries such as construction, manufacturing, and renewable energy. By facilitating the transport of these cumbersome items, low bedding services enable projects to proceed without disruption, maintain supply chain efficiency, and contribute significantly to industrial progress. As we continue to push the boundaries of what is achievable, these services adapt and evolve, meeting the ever-changing needs of modern industry.

When Do I Need Low Bedding Services?

Low bedding services come into play when the cargo you need to transport surpasses conventional freight services’ dimensional or weight limits. These circumstances generally involve transporting heavy machinery, construction equipment, oversized loads, or any other item that demands a higher load capacity and deck space. Industries like construction, manufacturing, renewable energy, and the military often require low-bedding services to move their specialized equipment. Furthermore, if your project involves moving items that are pre-assembled or challenging to dismantle, low bedding services provide an efficient solution. As a rule of thumb, considering low bedding services is a wise choice when your transportation needs involve large, heavy, or awkwardly shaped items.

History and Evolution of Low Bedding Services

Early Beginnings

As industries expanded in the early 20th century, the need for an efficient transportation system capable of handling heavy and oversized loads became evident. This led to the introduction of low-bedding services. The first low-bed trailers were rudimentary and limited in capacity. Still, they marked a significant leap in logistics, enabling industries to transport large machinery and equipment with greater ease and efficiency.

Modern Advancements

Fast forward to today, low bedding services have undergone tremendous advancements. Modern low-bed trailers are equipped with advanced technology and built with high-strength materials, enabling them to handle loads weighing up to several tons. Additionally, innovations such as modular trailers and hydraulic axle suspensions have amplified their capabilities, allowing for safe and efficient transport of increasingly larger and heavier loads. These advancements reflect the evolving needs of various industries and the continuous strive for improvement in the logistics sector.

Types of Low-Bed Trailers

Standard Low-Bed Trailers

Design and Usage

Standard low-bed trailers are the most common type used in the transportation industry. Their design is characterized by a drop in the bed’s height, which sits lower than the height of the flatbed, providing a low center of gravity. This feature allows for safely transporting tall loads, which would otherwise exceed height restrictions on roads or bridges. Standard low-bed trailers are versatile in their usage, accommodating a variety of loads, from industrial machinery to construction equipment.

Load Capacity

Typically, standard low-bed trailers can handle loads up to 40 tons. However, the load capacity can vary depending on the specific model and manufacturer. It is important to note that while these trailers can carry heavy weights, the load must be distributed evenly to prevent any complications during transit.

Specialized Low-Bed Trailers

Custom Features

Specialized low-bed trailers are tailor-made to suit specific needs, enhancing the capabilities of standard low-bed trailers. They may have additional axles to handle heavier loads, extended lengths for longer cargo, or reinforced decks for robust durability. Some specialized trailers also feature removable goosenecks for more effortless loading and unloading of cargo.

Applications in Specific Industries

Specialized low-bed trailers find their applications in industries where the transportation of exceptionally large or heavy cargo is required. This includes the wind energy sector for transporting wind turbine blades, the construction industry for moving large cranes, and the manufacturing sector for shipping heavy machinery. These trailers are instrumental in facilitating complex logistics operations, pushing the boundaries of what can be achieved in the transport sector.

Key Components of Low Bedding Services

Structural Elements

Frame and Deck

The frame and deck form the foundational structure of a low-bed trailer. The frame, typically constructed from high-strength steel, provides the necessary durability and rigidity to handle heavy loads. The deck, fabricated from either wood or steel, provides a flat, sturdy surface for cargo placement. It is positioned lower than regular flatbeds, resulting in a lower center of gravity, thus granting stability and the ability to transport taller items.

Axles and Suspension

The axles and suspension system are vital components of a low-bed trailer. They bear the load weight and provide stability during movement. A more significant number of axles indicates a higher load capacity. The suspension system, often hydraulic or pneumatic, absorbs road shocks, ensuring a smoother ride for sensitive cargo.

Safety and Security Features

Tie-Down Points

Tie-down points are crucial safety features on low-bed trailers. They provide secure points for attaching ropes, chains or straps to prevent cargo movement during transit. These points are strategically located across the deck, allowing for flexible and safe arrangement of various load types.

Load Stabilization Technologies

Load stabilization technologies, such as anti-slip mats and load levelling systems, further enhance low-bed trailers’ safety and security features. Anti-slip mats provide friction between the cargo and deck, preventing any possible movement. Load levelling systems adjust the weight distribution across the trailer, ensuring optimal balance and stability. These technologies play a pivotal role in preventing accidents and damage during transit.

The Process of Low Bedding

Preparing for Transportation

Load Assessment

The low bedding process begins with a detailed load assessment. This involves determining the cargo’s weight, size, and shape to be transported. The load assessment is critical for selecting the correct type of low-bed trailer and planning the most optimal transportation strategy.

Route Planning

Route planning is another crucial aspect of preparation. This involves evaluating the best transportation route and considering road conditions, overhead obstructions, and legal restrictions. A well-planned route ensures efficient and safe transport of the cargo.

Execution of Transportation

Loading and Securing Techniques

Once the preparation is complete, the transportation execution begins with loading the cargo onto the trailer. This is done using cranes or other heavy machinery. Once loaded, the cargo is secured using tie-down points and load stabilization technologies to prevent movement during transit.

Navigating on the Road

After the load is secure, the trailer is ready to navigate the planned route. The driver must be highly skilled to handle the unique challenges of driving a low-bed trailer, such as managing the vehicle’s low ground clearance and maneuvering oversized loads through traffic and narrow roads. Throughout the journey, constant monitoring is essential to ensure safety and to make necessary adjustments.

Example of Low Bedding Process

- Load Assessment: The process begins with a meticulous evaluation of the cargo. In this example, let’s consider a large industrial machine weighing 30 tons, which is significantly high. The machine’s specifications are noted, including its dimensions and any special handling instructions.

- Trailer Selection: Given the weight and size of the machinery, a standard low-bed trailer with appropriate load capacity is selected. The trailer’s lowered deck and robust frame suit it for transporting tall and heavy cargo.

- Route Planning: The transportation route is carefully planned. It is ensured that the chosen route has no low-overhead bridges that might pose a challenge for the high cargo. Moreover, the route is selected to have minimal traffic and good road conditions for a smoother journey.

- Cargo Loading: The machinery is carefully loaded onto the trailer with the help of a crane. The machine is placed on the deck to distribute its weight evenly across the trailer.

- Securing the Load: The machine is then secured to the trailer using tie-down points and straps. Anti-slip mats are placed underneath to prevent any movement during transit. The load levelling system is adjusted to ensure optimal balance.

- Transportation: Finally, the driver navigates the planned route, handling the vehicle’s low ground clearance and the oversized load. The cargo is constantly monitored during the journey to ensure safety and timely adjustment if needed.

Challenges in Low-Bedding Transportation

Transporting heavy loads using low-bed trailers presents unique challenges that require careful planning, skill, and adaptability to overcome effectively.

Navigational Challenges

Overcoming Road and Weather Conditions

Navigating a low-bed trailer on the road is a complex task. The driver must manage the vehicle’s low ground clearance while maneuvering oversized cargo through traffic and narrow roads. Additionally, adverse weather conditions such as heavy rain, snow, or strong winds can significantly affect the trailer’s stability and the cargo’s safety. This calls for drivers to have expert knowledge and experience handling such conditions to ensure safe and successful transportation.

Handling Permits and Regulations

Due to their size and weight, low-bed trailers often fall under special regulations and require permits for operation. This includes weight limits on certain roads, restrictions on transportation during specific times, or limitations due to low-clearance bridges or tunnels. Compliance with these regulations is crucial to avoid legal issues and ensure the safety of the cargo and other road users.

Technical Challenges

Dealing with Oversized Loads

The transport of oversized loads presents a significant technical challenge. These loads require special handling, securement, and placement on the trailer to ensure safe transit. Moreover, an oversized load’s weight distribution must be carefully managed for the trailer’s stability. This calls for specialized skills and technical knowledge from the transportation team.

Equipment Maintenance

Proper maintenance of the low-bed trailer is a critical aspect of its operation. Regular checks and timely repairs of the trailer’s frame, deck, axles, suspension system, and other components are necessary to uphold its integrity and performance. Poorly maintained equipment increases the risk of breakdowns and accidents and can lead to costly delays and damage to the cargo. Therefore, an effective maintenance routine is an essential part of low-bedding services.

The Future of Low Bedding Services

As industries evolve, low-bedding services are also experiencing significant changes. The future of this sector is headed toward innovative strategies and emerging technologies.

Emerging Technologies and Trends

The advent of technologies like IoT (Internet of Things) and AI (Artificial Intelligence) has opened up new avenues in low bedding services. IoT devices can facilitate real-time tracking and cargo monitoring, enhancing safety and efficiency. Conversely, AI could be used to optimize route planning, considering variables like traffic, road conditions, and weather. Autonomous driving technology is another potential game-changer, which, though in its nascent stages, may revolutionize long-haul heavy cargo transportation.

Conclusion

Low-bedding services are crucial in the rapidly evolving logistics and transportation landscape, especially in oversized and heavy cargo movement. There are challenges associated with this service, from navigational difficulties to overcoming technical hurdles, which necessitate intricate planning, expert handling, and an astute understanding of regulations. With emerging technologies such as IoT and AI, the sector is ripe for transformation, enhancing these services’ safety, efficiency, and reliability. In essence, low-bedding services are a vital cog in the machinery of global commerce, underscored by their operation’s complexity and their role in supporting various industries.

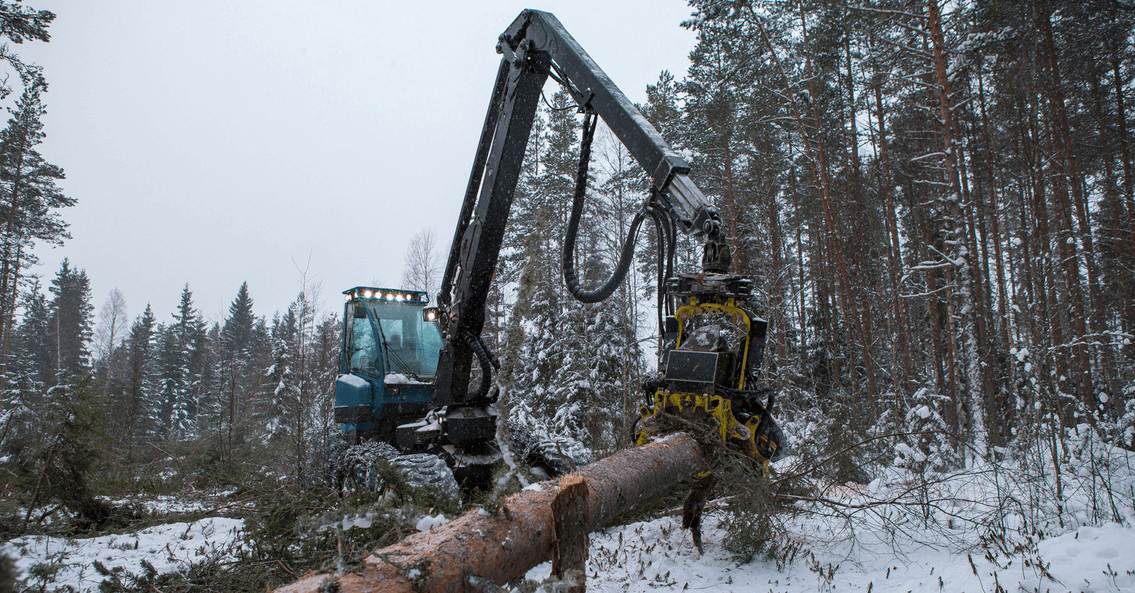

Experience unmatched expertise in logging, private wood services, and low-bedding equipment transport with SAN Forestry. Our unwavering dedication to safety, efficiency, and environmental responsibility guarantees that your projects are handled carefully. Don’t settle for anything less than top-notch quality and reliability. Contact Us today for a consultation and discover how our professional services can cater to your specific needs.