Logging in Alberta is not just an industry; it’s a vital part of our economy and environment, striking a balance between resource extraction and sustainable forest management. Central to any logging operation is the machinery — the heavy hitters that make it possible to safely and efficiently harvest timber from our vast forests. Modern logging isn’t possible without these powerful machines, which have revolutionized how we cut, transport, and process wood. From felling trees with precision to moving massive logs over rugged terrain, the technology behind logging equipment has come a long way. In this blog, we’ll explore some of the critical pieces of heavy equipment used in logging operations, showing how they contribute not only to the productivity of the logging industry but also to working safely within Alberta’s diverse ecosystems. Whether you’re involved in the logging industry or just curious about how those logs make their way from forest to facility, understanding the machinery involved is a great place to start.

Categories of Heavy Equipment Used in Logging Operations

Felling and Processing Equipment

- Chainsaws: The most basic and versatile tool in logging, used for felling trees and limbing downed trees.

- Feller Bunchers: Heavy-duty machines that cut and gather several trees before placing them in a designated area. Ideal for clear-cutting areas with their ability to work quickly and efficiently.

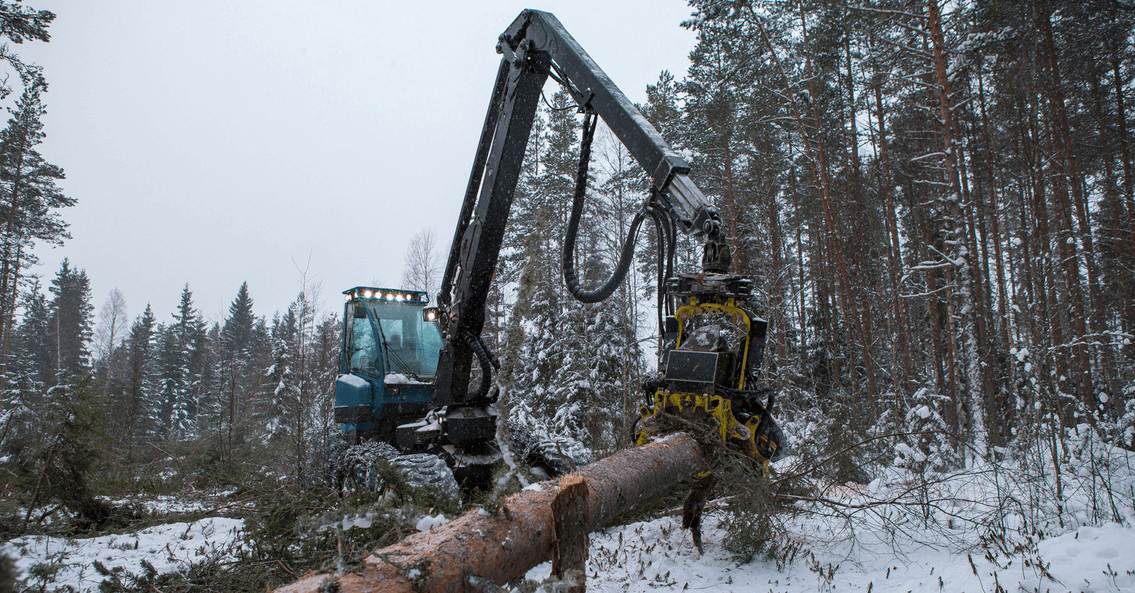

- Harvesters: Technologically advanced machines that can fell, delimb, and cut trees to specified lengths in one operation. Perfect for selective logging operations.

Extracting and Loading Equipment

- Forwarders: These vehicles transport logs from the felling site to a loading area, minimizing ground disturbance. They are equipped with a loading arm and are often paired with harvesters.

- Skidders: Powerful tractors designed to drag logs from the felling site to the landing zone using cables or grapples. Skidders can maneuver through rough terrain easily.

- Log Loaders: Specialized equipment for loading logs onto trucks or trailers for transport. They feature powerful hydraulics and can handle large loads efficiently.

Transportation Equipment

- Log Trucks: Designed to carry heavy loads of logs over long distances, these trucks are essential for transporting timber from logging sites to mills or shipping areas. They have robust frames and powerful engines to manage the weight and challenges of logging roads.

- Logging Trailers: Attached to log trucks, these trailers are engineered to maximize the load of timber that can be transported. Some are equipped with extendable frames to accommodate different lengths of logs.

- Railroad Cars: Railroad cars are an efficient option for larger-scale operations that need to transport logs over very long distances. Rail transport minimizes road wear and can be more cost-effective for cross-country log transportation.

Support Equipment

- Bulldozers: Used for clearing land and constructing roads to access the logging sites. Their powerful blades and heavy treads make them ideal for moving debris and grading land.

- Excavators: Equipped with specialized forestry attachments, they can handle various tasks, from digging to lifting heavy objects.

- Logging Trucks: Specifically designed trucks for transporting logs over long distances. Their unique build allows them to carry heavy and oversized loads securely.

Felling Equipment

The initial step in the logging process is cutting down trees. Felling equipment such as chainsaws, harvesters, and feller bunchers is critical. These machines can vary significantly in size and function, from handheld saws for more precise cuts to large, vehicle-mounted devices that can cut and gather multiple trees in one go. The goal is to efficiently cut the trees without causing any damage to surrounding trees or the environment.

Harvester

Among the most revolutionary pieces of fishing equipment is the harvester. Harvesters are sophisticated machines that not only fall trees but can also limb, top, and cut them to specified lengths on the spot. This multi-functional approach significantly reduces the time and physical labour needed for these tasks, enhancing the efficiency of logging operations. Equipped with advanced hydraulic systems and computerized measuring controls, harvesters can perform precise cuts, ensuring maximum yield from each tree and minimizing waste.

Feller Buncher

Another vital piece of heavy equipment used in logging operations is the feller buncher. Feller bunchers can cut and collect several trees before placing them in a designated area. This capability is instrumental in clear-cutting operations or preparing large timber volumes for transport. By combining the actions of cutting and gathering, feller bunchers significantly reduce the effort required to clear forest areas and prepare the logs for extraction. These machines come in various sizes and configurations to suit different terrain and tree sizes, including wheeled and tracked models for stability and mobility in uneven forest environments.

Extracting Equipment

Once trees are felled, they must be moved from the forest to the landing area. This task is accomplished by extracting equipment such as skidders, forwarders, and cable systems. These machines are designed to maneuver through the forest, overcoming obstacles to bring logs to a central location for further processing or transportation.

Skidders

Skidders are pivotal in the logging extraction process, designed to haul felled trees from the cutting site to the landing area. They do so by dragging the logs across the ground with cables or lifting them slightly off the terrain to reduce friction and environmental impact. Skidders are equipped with powerful engines and rugged tires or tracks, allowing them to maneuver through diverse forest terrains easily. Their ability to rapidly transport large volumes of logs efficiently minimizes the time logs spend on the forest floor, reducing potential damage to the undergrowth and soil structure.

Forwarders

Forwarders take the logging process a step further by transporting logs and stacking them neatly at the landing area. Unlike skidders, which drag logs behind them, forwarders carry loads entirely off the ground, lessening the environmental impact. They are equipped with a loading crane and a bunk where logs are securely placed for transportation. This method is particularly beneficial for sustainable forestry practices as it minimizes soil disturbance and prevents damage to the remaining trees and vegetation.

Cable Systems

Cable systems, also known as skyline logging, represent a specialized method of log extraction used in steep, rugged terrains where traditional ground-based machinery cannot operate effectively. These systems use cables mounted on towers or trees to suspend and transport logs from the cutting area to the landing. Using cable systems minimizes soil disruption and tree damage, making it an excellent option for environmentally sensitive areas. Depending on the specific requirements of the logging site, they can be set up in various configurations to optimize the efficiency and impact of extraction operations.

Loading Equipment

Loading equipment includes knuckleboom loaders, grapple loaders, and other machinery for lifting logs onto trucks or railcars. Its design focuses on efficiency and safety, allowing for rapid log movement while minimizing the risk to operators and ensuring the stability of the load.

Knuckleboom Loaders

Knuckleboom loaders are critical in logging operations and are prized for their versatility and precision. These loaders feature a hydraulic boom with a joint resembling a human finger, allowing excellent maneuverability when picking up and stacking logs. Their design enables operators to control the loaders with high precision, efficiently organizing logs in tight spaces. Knuckleboom loaders are also designed to be lightweight, reducing soil compaction and allowing for their installation on various platforms, including trucks and trailers. This flexibility means they can load logs directly onto transport vehicles at the logging site, streamlining the transition from forest to processing facility.

Grapple Loaders

On the other hand, grapple loaders are known for their sheer power and capacity. Equipped with a strong grapple claw, these loaders can grip multiple logs at once, significantly enhancing the speed of loading operations. The grapple’s design ensures a secure hold on the logs, minimizing the risk of dropping or damaging the cargo during transport. Grapple loaders are typically mounted on heavy machinery like forwarders or specialized vehicles, providing the necessary stability for handling large timber volumes. Their robust construction and powerful hydraulics make them indispensable in logging operations, especially when dealing with large-diameter trees or dense woodlands.

Efficiency and Safety

The design and implementation of loading equipment prioritize efficiency, productivity, and the safety of logging personnel. Modern loaders are equipped with enclosed cabs, protecting operators from the elements and noise and significantly reducing the risk of injury from falling logs or machinery. Advanced ergonomic controls and visibility enhancements, such as cameras and sensor technology, further ensure operator safety and operational accuracy.

Transport Equipment

The logs must then be transported from the forest to mills or storage areas. This category includes trucks, trailers, and sometimes specialized railcars designed to handle the heavy and uneven load of logs. This equipment is built for durability and long-distance travel, ensuring that logs arrive at their destination in good condition.

Trucks and Trailers

Trucks and trailers are essential for log transport. They are built to endure the rough conditions of forestry roads with heavy loads. Logging trucks have strong suspension systems to handle uneven terrain, ensuring efficient log transport from remote areas to processing plants. The trailers have stakes to securely hold logs, preventing them from shifting during transit. Their adjustable stakes accommodate various log sizes, improving load efficiency and safety.

Rail Transport

When logging sites are far from processing facilities, rail transport is cost-effective. Specialized railcars carry more volume than trucks, lowering the costs of long-distance timber transport. Dedicated rail lines to logging areas ensure efficient timber movement to sawmills, pulp mills, and export docks, making rail an essential part of the timber supply chain in large forestry operations.

Support Equipment

In addition to the heavy equipment used in logging operations, numerous types of support equipment are also used. This includes bulldozers, excavators, and road graders for building and maintaining roads and paths in logging areas. Without this support machinery, accessing the forests and moving the heavy equipment and logs would be significantly more challenging.

Each category of logging equipment plays a vital role in the operations, working together to ensure that logging in Alberta is carried out efficiently, safely, and sustainably.

Careers as a Heavy Equipment Operator

Pursuing a career as a heavy equipment operator in the logging industry presents an opportunity to play a crucial role in timber harvesting and management. These professionals are skilled in operating the machinery essential for logging, such as feller bunchers, skidders, and loaders, ensuring the efficient, safe, and environmentally responsible movement of timber from forest to mill. The role demands physical aptitude, the ability to work in challenging outdoor conditions, and a strong commitment to safety protocols and environmental stewardship.

Heavy equipment operators often undergo hands-on training to gain hands-on experience with specific machinery. Certifications, while varying by region, typically underscore a professional’s competence and adherence to safety and operational standards. With advancements in logging technology, operators must also keep pace with new equipment and automation trends, making continuous learning a part of the career path.

Employment opportunities for heavy equipment operators exist within logging companies, forestry service contractors, and governmental bodies involved in land management and conservation projects. Their role is pivotal in balancing the economic demands for wood products and ensuring sustainable forestry practices. As such, heavy equipment operators contribute significantly to the forestry sector’s global challenges, including climate change mitigation, biodiversity conservation, and the sustainable management of forest resources.

Conclusion

The intricate operation of logging in Alberta, supported by a wide array of specialized equipment and skilled personnel, exemplifies the complexity and importance of this industry. From the initial harvesting of timber using advanced machinery to the meticulous process of transporting logs to mills, every step focuses on efficiency, safety, and environmental sustainability. Heavy equipment operators play a critical role in this process, leveraging their skills and knowledge to ensure the smooth and responsible extraction of forest resources. The logging industry contributes significantly to Alberta’s economy and global efforts to manage forests sustainably. As technology advances and the world’s focus on environmental conservation intensifies, the industry’s practices and equipment will continue to evolve, ensuring that logging remains a vital yet sustainable economic activity.

Pursuing a career as a heavy equipment operator provides a distinctive mix of physical engagement, skill enhancement, creative problem-solving, and a chance to contribute significantly to the development of our environment. If you have a passion for working in the open air, handling machinery, and are seeking a career with promising opportunities, choosing the path of a heavy equipment operator might be the perfect option for you.

San Forestry offers competitive salaries and benefits and ample opportunities for professional growth and development within the organization! We take pride in providing our employees with a safe work environment where they can thrive professionally while having fun at the same time! If you think you have what it takes to join our team of Class 1 Drivers and Heavy Equipment Operators, then don’t wait – apply today!